No Acceleration, P2102 P2111 | Mercedes CLS

🚗 2014 Mercedes Benz CLA 250 2.0L Turbo

- Car starts, but the check engine light is on and the car doesn’t accelerate.

- It from a body shop. Prior to bodyshop was running fine.

🩺 Diagnosis

- ECM DTC’s

- P2102-00 The Throttle valve actuator has a short circuit to ground.

- P2111-00 The throttle valve is stuck on.

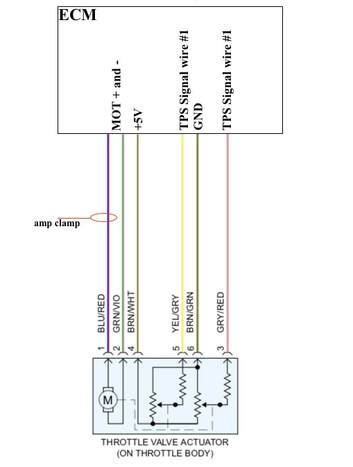

First, let’s look at the diagram. There are two wires that control the motor, and two 5V throttle position sensors.

- Could it be just a stuck throttle plate? Yes, but getting there is not as easy as testing electrical basics first. So, I’ll check that later.

- Power to ECM?

- I remember that some cars have a dedicated fuse for throttle (e.g. ETCS fuse on Toyotas), and if it’s burned, throttle won’t have power. The diagram for this car doesn’t help in figuring that out. So I have to test all B+ and GND wires that enter ECM directly.

- Tested terminal 30 (constant B+), ok.

- Terminal 15 (ignition on B+. Comes from the Front SAM module). Here I learned something new about Mercedes. When I used a test light to test for battery power on terminal 15, 12V that was there before suddenly disappeared. I thought for some time that it could be the problem. But turned out that on this car, terminal 15 had a “current limiter” in the Front SAM, meaning that test light drew more power than was allowed by SAM, so it turned that power off. Anyways, terminal 15 is ok here.

- Tested ECM grounds, ok.

- Does the throttle plate motor work?

- Disconnected ECM and briefly supplied power to the throttle body motor. Heard a clunk, meaning wires and motor should be fine.

- Testing TB motor and TPSs (throttle position sensors)?

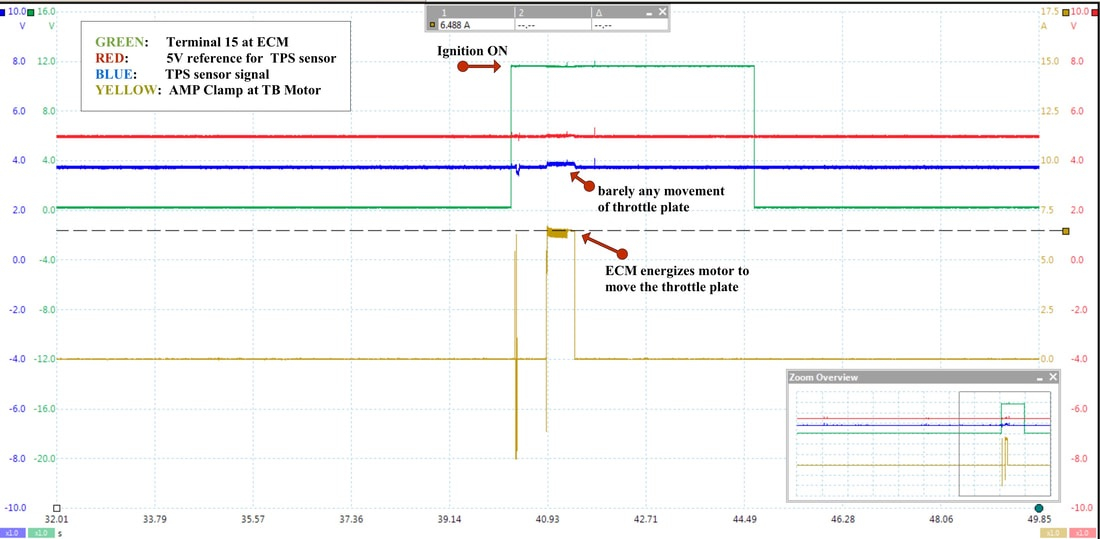

- I cannot test power on throttle body motor wires directly, because (as you will see) the computer varies the direction of the current by using PWM (pulse width modulation). In addition it actuates it only for a brief time with after ignition on and engine off.

- Testing wires for the TPS gave me normal readings. +5V, ground, and two signal wires. Supplying little power (0V – 5V) to the signal wires and watching live data change on the scantool revealed that wiring to the TPS is good.

Now, before starting to take things apart to get to the throttle plate, I wanted to see if ECM is trying to actuate the throttle body motor.

So, I hooked up my PicoScope with an amp clamp around the motor wire, terminal 15 wire, 5V TPS wire, and TPS signal #1 wire.

Note that with ignition on ECM tries to move the throttle plate with current peaking at 6.5A. At the same time, TPS sensor doesn’t report any significant movement (should be ~1V – 4.5V).

Now there is nothing else left to check, so I had to stop avoiding getting my hands dirty and see what is going on inside the throttle body. Should have done that in the beginning.

Would you look at that 🙂 Someone at the body shop has left a mask paper inside… unless it has been sucked in somehow.